Latest work of our Electronics Engineer: Summary of PCB designs & experiments

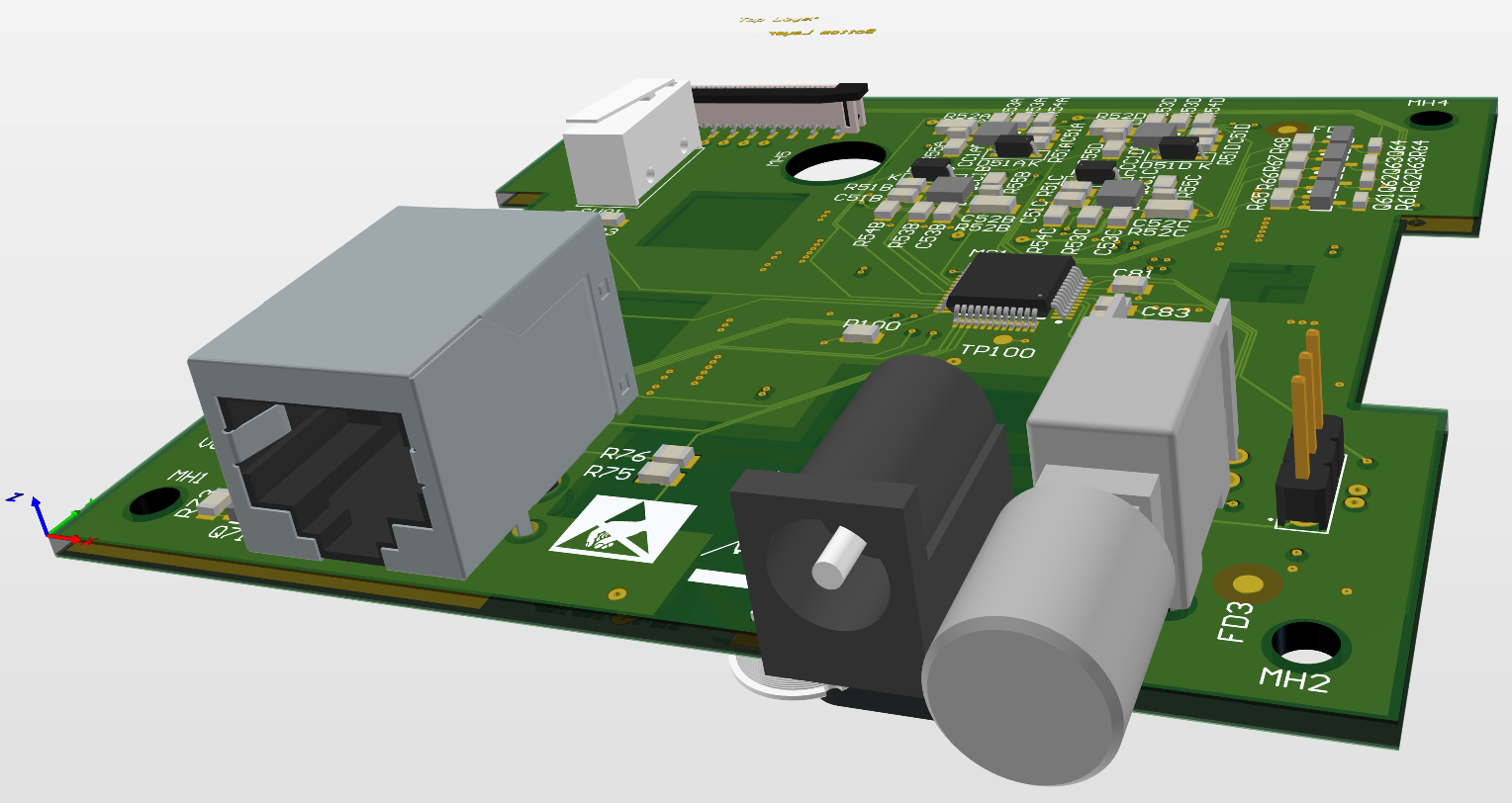

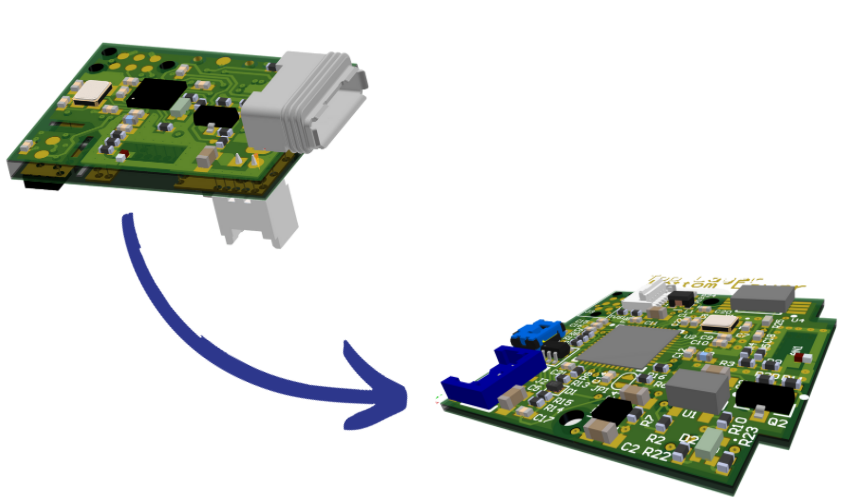

Recently I have been finalising a design consisting of five PCBs. This has involved performing tolerance and thermal analysis on the design ensuring manufacturing variations and changes in external temperature will not significantly impact devices' or the circuit's performance. Once the design was complete and a design rule check had been carried out, using the standards and rules set by IPC, it was submitted for review where the Schematic Design calculations, PCB, Production files, original source CAD and BOM are peer reviewed. Ay queries or comments are discussed with the peer reviewer and any actions agreed before implementing in and iterating the design. The revised files are then resubmitted for further review.

I have also been investigating the performance of a battery that was reported to be failing under certain circumstances. This involved capturing the battery's charge and discharge performance and comparing this to the battery datasheet. A comparison was made to an alternative battery, similar in specification, to allow a performance comparison to be made and final conclusion obtained. The test set up, method and results were then captured in a test report.

Edits were made to an inherited design where changes to the mechanical enclosure required the PCB to be relayed out. The global component shortage caused some of the component used in the design to be unavailable, interrupting the client’s plan and timescale. This meant alternative components had to be sourced and schematic edited to use the new components before the re-layout of the PCB could commence. When re-laying out the PCB, it was essential to work closely with the mechanical design engineer(s) to ensure the PCB fit inside the strict space available. The global component shortage meant the alternative components sourced were of a larger package size, presenting an additional challenge when space is tightly constrained.

Finally, I have been looking at investigating a product which our client reported was failing but they were unsure what the root cause was. I have been testing these products, trying to replicate the error to determine the cause with the goal of recommending a course of action to prevent the failure mode in the future. This involved creating a test plan, conducting the test and noting the results, then adapting the test plan as more results were obtained since the steps to recreate the failure mode were unknown when beginning the investigation. The test procedure, results, conclusion and a possible solution to the causes of the failure mode were then summarised in a test report.